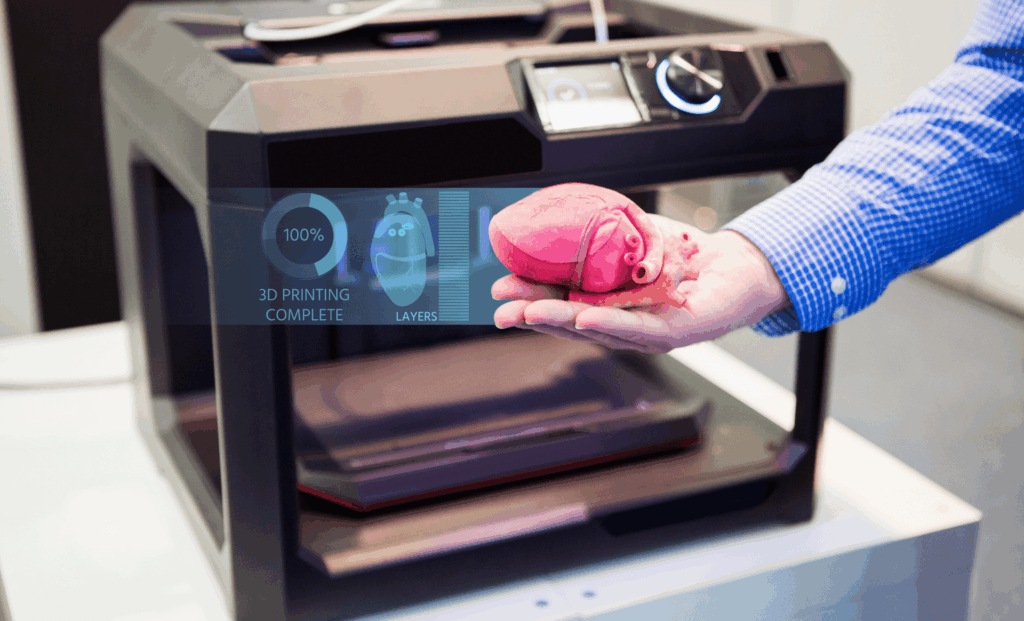

A breakthrough from the University of Virginia has opened new possibilities in 3D-printable materials, capable of transforming both medical devices and advanced battery technologies. The innovation revolves around a stretchable, biologically compatible material that could help improve organ transplants and drug delivery systems. The research, published in Advanced Materials, has shown promise for enhancing solid-state batteries.

The Stretchable Revolution: PEG Gets an Upgrade

Polyethylene glycol (PEG) has been a staple in biomedical engineering, used in everything from tissue engineering to drug delivery. However, traditional PEG networks often suffer from brittleness, preventing their use in flexible and dynamic environments. Researchers at the University of Virginia’s Soft Biomatter Laboratory, led by Liheng Cai, have cracked the code by reimagining the material’s molecular structure. They introduced a

“foldable bottlebrush” design that stores length at the molecular level, much like how rubber stretches, making the material both strong and flexible. “Our group discovered this polymer and used this architecture to show any materials made this way are very stretchable,” Cai said.

This innovative design allows PEG to stretch without compromising its structural integrity, opening doors for its use in larger, more complex biomedical applications like synthetic organ scaffolds. The material’s potential to stretch and remain intact could be a game-changer for medical implants and prosthetics, providing much-needed flexibility in environments where movement and adaptation are essential.

A New Way to Build: 3D Printing and Flexibility

One of the most exciting aspects of this discovery is the ability to 3D-print these advanced materials with varying degrees of stiffness and flexibility. By using ultraviolet (UV) light, the researchers can shape the material into intricate forms that meet specific needs. As Baiqiang Huang, a Ph.D. student involved in the project, explained,

“We can change the shape of the UV lights to create so many complicated structures.”

This ability to create both soft and stiff structures that remain stretchable by design opens up numerous possibilities for creating custom implants, prosthetics, and even scaffolding for organ regeneration.

The material’s adaptability doesn’t stop at its physical properties; it also promises to revolutionize medical devices by offering new ways to design structures that mimic human tissues. Its biologically compatible nature ensures that it could be safely used within the human body, further enhancing its utility in the field of medicine.

Beyond Medicine: A New Frontier for Solid-State Batteries

While the material’s medical applications are groundbreaking, its potential extends to energy storage technologies as well. The same polymeric network that makes the material stretchable and strong also improves its electrical conductivity, making it an excellent candidate for use in solid-state batteries. Solid-state batteries are seen as the future of energy storage, offering higher safety and performance compared to traditional lithium-ion batteries.

“This property highlights the new material as a promising high-performance solid-state electrolyte for advanced battery technologies,” Cai said.

The researchers at the University of Virginia are now focused on refining the material for use in these advanced battery systems. Their work could lead to batteries that are not only safer and more efficient but also more flexible, enabling new possibilities for wearable tech, electric vehicles, and beyond. “Our team continues to explore potential extensions of the research in solid-state battery technologies,” Cai added, hinting at exciting developments in the future.

The Potential of Combining Materials for Custom Applications

Looking ahead, the team is exploring how PEG can be combined with other materials to create versatile 3D-printable composites. This would allow for even more customized designs, with varying properties like conductivity, flexibility, and strength tailored to specific needs. Whether in the biomedical field or energy storage sector, these materials could be precisely engineered to meet the requirements of next-generation technologies. The ability to 3D-print with such precision is a step toward creating entirely new classes of materials, pushing the boundaries of what is possible in both medicine and technology. As detailed in Advanced Materials, these innovations open the door to safer organ transplant technologies, more effective drug delivery systems, and advanced solid-state batteries.